友信貿易 Yushin Trading Co., Ltd.

- 03-6457-1138

- お問い合わせ

New solutions for a new aera.

The time for companies to merely procure items to sell to customers has ended.

We believe that as trading company of tomorrow, we must be able to provide solutions for the customer’s process of developing and manufacturing products.

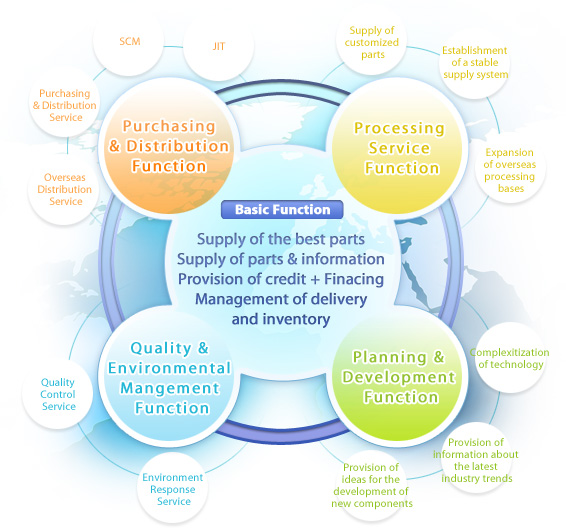

For this reason, YUSHIN TRADING has reinforced four functions, which derived from the traditional functions as a trading company: the function to purchase and distribute, the function to manage quality and the environment, the function to provide processing services and the function to plan and develop to carve out the path to the next generation.

As suggested, the functions and roles of the YUSHIN TRADING consistently change along with the needs of each era , which could provide added value that goes beyond the boundaries of trading companies of the past.

Purchase and Distribution Service

YUSHIN TRADING will carry out the functions of the customer’s purchasing department such as purchasing and distribution. This service will shorten inventory time as distribution operation is streamlined. For purchasing operation, we select the most suitable manufacturers from an expanding selection of manufacturers throughout the world to order components from and thoroughly carry out quality control and delivery management by making full use of our expertise. We can deal speedily with faulty goods. By making full use of their expertise and know-how in this field, they are now actively developing an integrated international purchasing and distribution, and also operating purchasing and distribution in developing countries, especially in Southeast Asia and China.

About Adhesive

Yushin Trading sells all kind of Adhesive. When you look for Adhesive which is best for you.please check it.

Process

| type of adhesive | One-part solventless agent providing quick curing at normal temperature | rubber adhesive | One liquid adhesive | Two mix liquid adhesive |

|---|---|---|---|---|

| Clean of adhesive surface |

Use cotton yarn, sandpaper or detergent to clean up the oil, water, rust, dust, paint, release agents, etc. adhered to the surface. Particular attention should be paid on rubber, plastic , especially on mold release agent. Make the adhesive surface as smooth as possible. Wood, concrete should dry fully. |

|||

| mix |  |

Get the necessary amount among the ratio of the main agent and hardening agent, fully mixing after measuring. Thus the two liquid mix spit out device can be used. | ||

| smear | Use the bush or the scraper to smear equally on the two sides of the bonding material. The smear device can be used here too. | Use the brush, scraper or trowel on one side of the bonding material, brush, spatula or trowel, roller, etc., smear devices can be used according to different purposes, use instant adhesives from the container or use the special spit device directly. | ||

| Air-drying time | To achieve adhesion, both smeared sides of the adhesive material must wait 5 to 10 minutes to adhere. For the initial process without adhesion, the adhesion can be done immediately. | Before the volatile of the solvent, the adhesive material should be placed for 5 to 10 minutes. |  |

|

| adhere | After air-drying time, to exert strong pressure temporarily to generate early adhesion strength. However, some maintenance time is needed prior to full hardening. | No waiting time for adhesion after the single side smear. | ||

| Squeeze and fix |  |

Several hours is needed to reach the practical use stage, in order not to move the adhesive material we need to use clips or clamps and other necessary tools to fix and maintain for a period of time after the adhesion. | ||

| Hardening Maintenance | Several hours is needed to reach the practical use stage, to maintain under the condition of squeezing and fixing. Lay aside for 3 hours (fully hardening need 24 hours) |

● resin solvent agent |

||

| Clean-up | The smearing tool should be cleaned immediately with solvents after using. Also, the hose front, the glue attached to the edge of plastic tanks should be carefully wiped off, to ensure that the lid is tight with the bottle to prevent the interior material from hardening. |

|||

About Grease

Yushin Trading sells all kind of lubricant .we collect history and Classification and characteristics of lubricants,please cheak it.

Comparison between lubricant lubrication and grease lubrication

| Items | lubricant lubrication | grease lubrication |

|---|---|---|

| Oil add equipment | The seal of the bearing may result in long-time lack of lubricant supply | Need continually add oil to lubricate parts (drip, splash, circulate, etc.) |

| Essential oil | Can control it into the minimum necessary | Need a lot |

| Lubrication type | Pure | Complex |

| Oil leakage | No fear of leakage as the lubricant sealed ability. | Need to notice the sealing structure |

| High speed revolve | Limited | Achieve through the oil added method |

| Foreign matter remove | Difficult | Remove continuously through filtration, centrifugation |

| Cooling Capacity | Impossible | High potential |

| Friction loss | Large in general condition. However, torque decreased as the channeling effect of rotation axis |

Generally very little |

The comparison of the grease Characteristic by the increase butterfly agent

| Thickener Type | Drop temperature | performance | The highest temperature to bear | price |

|---|---|---|---|---|

| Calcium Grease | 75℃ | Good water resistance, but poor heat resistance | 70℃ | △ |

| Calcium-based grease compound | 180℃ | Heat resistance, water resistance, rust, good mechanical stability of the general | 130℃~180℃ | ◎ |

| Aluminum Grease | 85℃ | Good adhesion, corrosion resistance and good water resistance, poor mechanical stability and heat resistance | 50℃ | △ |

| Composite aluminum grease | 150℃ | Adhesion, heat resistance, good water resistance, rust, good, good mechanical stability | 120℃~180℃ | ◎ |

| Lithium Grease | 170℃ | Shear stability, good heat resistance, water resistance and good anti-rust | 130℃~150℃ | ▲ |

| EP Lithium Grease | 170℃ | Heat resistance, water resistance, rust, good, good extreme pressure performance | 130℃~150℃ | ▲ |

| EP Lithium Complex Grease | 180℃ | Heat resistance, water resistance, rust resistance, mechanical stability, good extreme pressure | 130℃~180℃ | ◎ |

| Molybdenum disulfide lithium grease | 170℃ | Heat resistance, water resistance, rust, good, good extreme pressure performance | 130℃~150℃ | ▲ |

| Bentonite Grease | 250℃ | Good heat resistance, good water resistance, rust and poor | 150℃~200℃ | ◎ |

| Polyurea Grease | 250℃ | Heat resistance, oxidation resistance, water resistance, rust, good, good mechanical stability | 150℃~200℃ | ◎ |

| Fluorine grease | 无 | Corrosion resistance, heat resistance, oxidation resistance, water resistance, rust resistance, good mechanical stability, etc. | 250℃~290℃ | ● |

●:Very expensive、◎:Expensive、▲:Moderate 、△:Cheap